|

| |

|

| |

|

| |

Rubber Mixing Mill |

| |

|

| |

|

| |

|

| |

We have been widely appreciated in the market for our ability to offer a wide range of supreme quality Mixing Mills also known as Two roll mill with anti friction spherical Roller bearings. The heavy-duty stands are firmly bolted to the bed, which provides vibration-free operation. Moreover, our worm and worm wheel arrangement offers accurate roll gap effortlessly. Our machines can be mounted on vibro mounts which eliminates grouting foundation.We are the leading Manufacturers and exporters of Rubber Mixing Mill

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

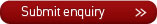

Vacuum Moulding Press |

| |

|

| |

|

| |

|

| |

| Description / Specification of Vacuum Moulding Press |

|

We are involved in offering a wide range of Vacuum Moulding Press to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Vacuum Moulding Press. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

- Sturdy design

- Highly durable

- Application specific design

|

| |

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

Rubber Bale Cutter |

| |

|

| |

|

| |

|

| |

VIKAS INDUSTRIES Rubber Bale Cutters are specially designed for economy, durability, ease—of—use and versatility. These machines are widely used for cutting rubber bales in different sizes. The steel hardened rollers ensure smooth movement of the bale through the machine. Semi and fully automatic cutters are perfectly suitable for toughest natural and synthetic rubber bales.

Inclined cutters are fed with continuous bales. The steel alloy blades cut the bales into pre-determined size of selected thickness. Bales are automatically discharged with the help of rollers. These hi-tec machines can also be provided with conveyors as per the demand of the clients.

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

Compression Press |

| |

|

| |

|

| |

|

| |

| Description / Specification of Compression Press |

|

We are involved in offering a wide range of Compression Press to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Compression Press. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

- Sturdy design

- Highly durable

- Application specific design

|

| |

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

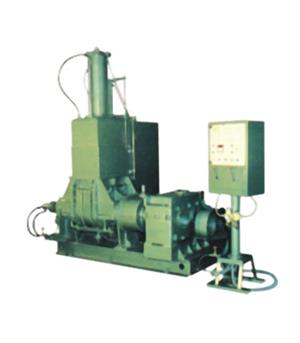

Dispersion Kneader |

| |

|

| |

|

| |

|

| |

| Folling Are The Specifications For The Machine : |

| |

|

Model

|

Capacity Ltrs. |

HP

|

| VIH-1 |

25 |

30 |

| VIH-1 |

35 |

50 |

| VIH-3 |

55 |

75 |

| VIH-4 |

75 |

100 |

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

Rubber Moulding Hydraulic Press |

| |

|

| |

|

| |

|

| |

| The application of Hydraulics in Rubber Processing though Hydraulic Presses is most convenient and effective method 'VIKAS' Upstroking. Hot Platen Hydraulic Presses serve the purpose more efficiently and conveniently presses for precured tred Rubber. Vee Belt conveyor Belt Marking Flp Moulding and such other special purpose Hydraulic Presses are with in the range of manufacturer for whch 'VIKAS' are well-known. Detail available against enquiry. |

| |

The Table Below Indicates Specifications For And frequently Sold Vikas Hydraulic Presses

(Electircally or steam Heated ) : |

| |

|

Series

|

Hot Platen Size in cm

|

Capacity in tones

|

RAM Dia in mm

|

| VIH-1 |

30 x 30 |

40 |

150 |

| VIH-2 |

40 x 40 |

65 |

200 |

| VIH-3 |

50 x 50 |

100 |

250 |

| VIH-4 |

60 x 60 |

150 |

300 |

| VIH-5 |

70 x 70 |

200 |

350 |

| VIH-6 |

80 x 80 |

260 |

400 |

| VIH-7 |

90 x 90 |

330 |

450 |

| VIH-8 |

100 x 100 |

410 |

500 |

| VIH-9 |

120 x 120 |

590 |

600 |

| In all the Series |

: Working Pressure – 210 kgs/cm²

: Stroke – 400mm

: Daylight Nos. 3-4 |

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

Hot Feed Ruber Extruding Machines |

| |

|

| |

|

| |

|

| |

| "VIKAS" Extruders Are Manufactured in the Following Range : |

| |

|

Model

|

Diameter or Screw mm

|

Driving Motor HP

|

Production Capacity Kgs. Per Hr

|

| VEX-55 |

55 |

5 |

35 |

| VEK-75 |

75 |

10 |

90 |

| VEX-100 |

100 |

15 |

150 |

| VEX-115 |

115 |

20 |

200 |

| VEX-150 |

150 |

60 |

500 |

| VEX-200 |

200 |

100 |

750 |

| In all the Series |

: Screw RPM

: 35/40 for Fixed Speed Extruder |

|

|

| |

|

| |

|

| |

|

| |

|

|